.

How to Clean and Reuse the Water From Your Cannabis Hydroponic System

Growing hydroponic weed creates wastewater than can't just be disposed of willy-nilly. Find out how to reuse it, or dispose of it properly. Mother Nature will thank you!

If you grow weed using a hydroponic setup, then you might wonder what you should do with the water once you’re done with it. Can you just throw it away? The short answer is: no.

If you intend to grow again, then you can sterilise and reuse your water. If you don’t intend to grow again, then there are responsible ways to dispose of it.

In this article, we explore three ways to clean hydroponic water, explain how to dispose of it, and take a quick look at how to clean a hydroponic system.

Contents:

Do You Have to Change the Water in Your Cannabis Hydroponic System?

When growing cannabis hydroponically, a time comes when growers might want to replenish the water in the system. This helps to combat the buildup of bacteria, algae, and minerals—all of which can damage plants and the overall system.

Some growers choose to do this when they flip their plants from the vegetative stage to the flowering stage. Others choose to do it between crops, and use the same water for an entire grow cycle. Either way, your system and plants will eventually require clean water.

While it’s often easiest to just throw out the old water and use new, clean water, there are times when you might want to reuse the water you already have. If this is the case, then it’s entirely possible—you just need to clean it!

What Are the Benefits of Water Reuse?

There are two main benefits of reusing water in a hydroponic system, and both have to do with the environment:

- It saves water: Hydro systems, if used efficiently, actually use less water compared to soil-grown cannabis. If you reuse water, then you can reduce the amount used even more, making your grow even more environmentally friendly. If saving water is the goal of hydro setups, then reusing water is a must.

- It minimises environmental pollution: Water that has been used to grow plants hydroponically is unnaturally rich in minerals. When this is dispersed into the natural environment, it can disrupt the natural balance of ecosystems. En masse, the concentrated water from all of the world’s hydroponic growing operations damages water systems and soil. If you clean and reuse water, then you can avoid causing this damage, at least to some degree.

How to Clean the Water in Your Cannabis Hydroponic System

Hopefully, you’re now inspired to clean and reuse your hydroponic water, rather than discard it. If so, then there are three main methods that you can use. One thing to note is that all of these methods require some equipment, and will probably be highly impractical if you’re only growing on a small scale. With the exception of UV treatment, the below methods are most suitable for commercial grows. If you’re a casual home grower, then UV is probably your best bet.

1. Pasteurisation

Pasteurisation is essentially very fast boiling. The way a pasteuriser works is by moving water between two heat exchangers. As it passes into the second, the water is heated very quickly to around 100°C. After 40 seconds, it is then returned to the first heat exchanger, where it is cooled. Once cool, it is ready for reuse.

Pasteurisation totally sterilises water in terms of bacteria and algae, but it also breaks down the mineral content, essentially taking it back to zero.

You can pick up a pasteuriser for hydroponic water online or in specialist shops. The main problem with these machines is that the mineral content in the water can, over time, damage them, reducing their efficacy.

Pros of Pasteurisation

- Completely sterilises water

- Machines can be bought fairly easily

- Simple to use

- Removes mineral content from the water

- Completely nontoxic

Cons of Pasteurisation

- Machines become damaged by mineral content of water

- Expensive

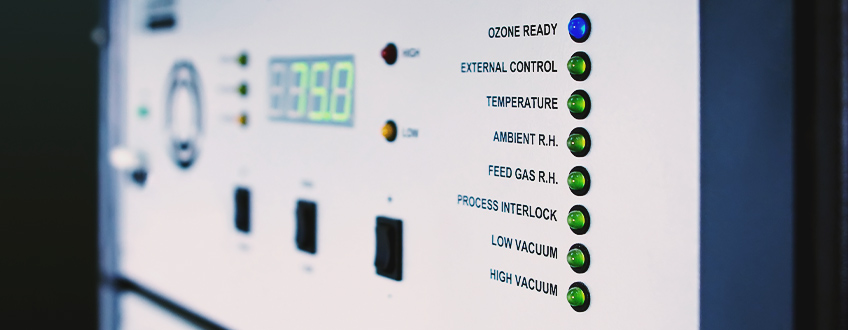

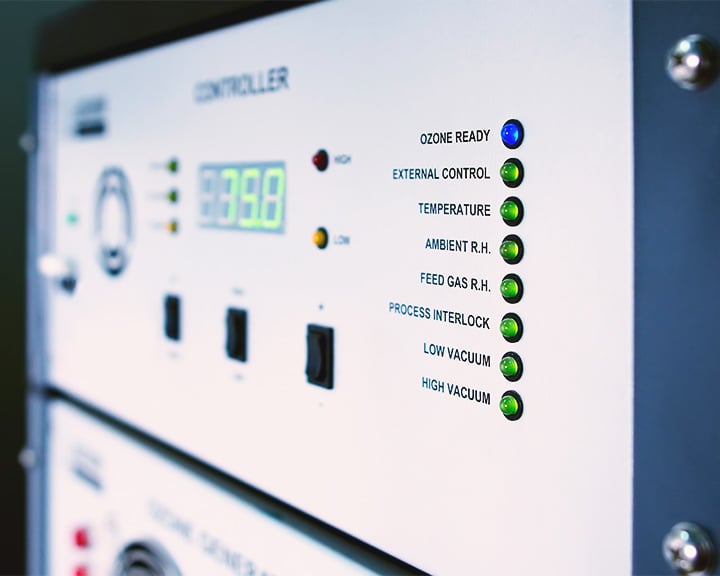

2. Ozone Sterilisation (Ozonation)

Ozonation uses ozone molecules (O₃) to sterilise water. Rather than sourcing these from the outer atmosphere, special machines break down oxygen molecules (O₂). Then, the lone oxygen atoms bind to O₂ molecules to form ozone molecules (O₃). This is then pumped into the water. Ozone molecules kill bacteria and algae, and break down minerals.

These molecules are not pollutants and don’t damage the atmosphere once the process is complete, meaning that ozonation is a clean process.

Pros of Ozone Sterilisation

- Effective at sterilising water

- Nontoxic byproduct

- Breaks down minerals

Cons of Ozone Sterilisation

- Specialist machines are expensive

- Overkill for small operations

- Requires a specialist setup

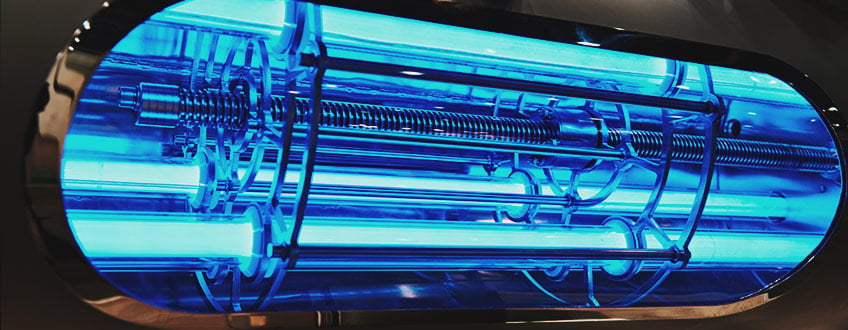

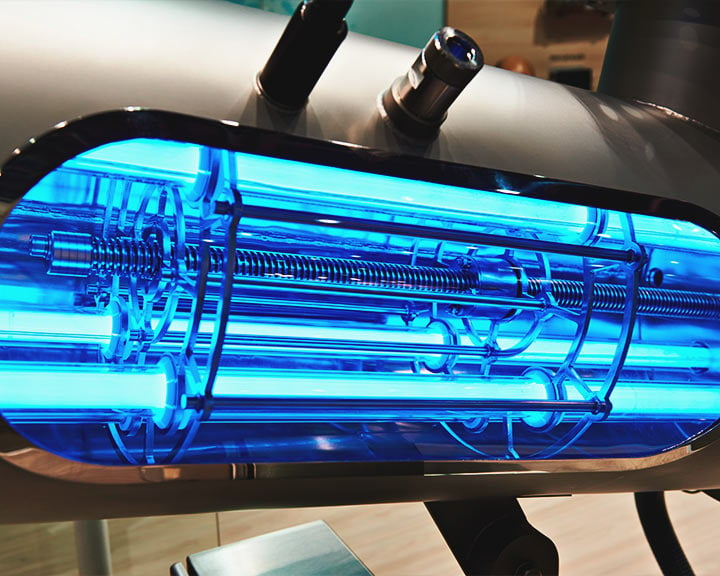

3. UV Disinfection

UV disinfection is yet another entirely nontoxic way to sterilise water. This method uses only UV light to kill off bacteria and algae. Such a technique is used across the world to clean human water sources, so it can be trusted as highly effective. However, unlike the previous two methods, it does not remove minerals from the water, which means you might need to filter it properly before using it again.

UV cleaning systems aren’t too expensive and are fairly accessible, making them a suitable choice for those who are growing at home. Although, you’ll have to take into account the extra cost and effort of filtering the minerals out of your water.

Pros of UV Disinfection

- Clean and effective

- Easiest option for home use

Cons of UV Disinfection

- Doesn’t remove minerals from water

How to Dispose of Hydroponic Wastewater

If you choose to not reuse your hydroponic wastewater, it’s important that you don’t just throw it down the drain or pour it into the garden. If you do this, the high concentrations of minerals will find their way elsewhere and do some damage.

To properly dispose of it, first mix it with clean water, such as tap water, at a 1:1 ratio. Then, use the solution to water self-contained potted plants. This way, the nutrients will become trapped in this soil and slowly absorbed by the plants. This stops it from entering the wider environment.

Alternatively, some claim that you can also pour it onto a compost pile, to good effect. Supposedly the nitrogen helps the process of decay in the pile. Later on, when the nutrients are diluted and used, this compost can then be harnessed to grow more plants.

How to Clean the Rest of Your Cannabis Hydroponic System

To keep a system running properly, you’ll also need to clean the mechanical parts, otherwise a buildup of bacteria and minerals will damage both the system and your crops. It can actually be quite a complex process, but here’s an overview.

1. Disassemble Your System

This will differ depending on what system you're using. Maybe you’ve made a very simple one yourself, or perhaps you’ve bought a very complex, intricate one. Either way, disassemble pumps, pipe work, and any parts where water passes through.

2. Clean the Smaller Parts

Fill your reservoir with water and add around 125ml of 3% peroxide for every 5 litres of water. Don a pair of washing gloves and get cleaning!

Pipes, pumps, caps, and components can all be cleaned in here. Use a brush and scrub everything until it looks pretty new. Focus particularly on parts where there’s residue buildup.

3. Clean the Substrate

If you’re using a substrate such as Rockwool, then these can be sterilised and cleaned. You can do so by boiling and then drying them out.

4. Clean the Larger Items

Using another peroxide solution, scrub down any growing chambers and the reservoir. Get them shiny and clean (or as good as possible). The harder you work now, the happier your next crop will be!

Clean Hydroponic Water Grows Great Cannabis

Sterilising and reusing the water from your hydroponic grow is, if you can do it, beneficial to the environment. And if you can’t do it, because, for instance, your operation is too small to warrant the equipment, then ensure that you dispose of the water in a sustainable way—such as diluting it and watering potted plants.

Using clean water and clean systems is really important when growing hydroponic cannabis. Plants in these systems are much more susceptible to infection and nutrient imbalances, so take care!