.

Why Does CRC Make Better BHO?

Color remediation column (CRC) tech improves the BHO extraction process. This piece of kit goes one step further in removing solvent residues and plant constituents that make BHO look dark and taste harsh. BHO created using CRC boasts a golden and translucent appearance, tastes much more smooth, and provides more THC and terps in every hit.

Contents:

Butane hash oil (BHO) entered popular cannabis culture in 1999 following a forum post guiding users on how to make the substance. Today, the solvent-based cannabis extract remains a popular choice, offering a condensed, potent hit of terpenes and cannabinoids.

Despite its powerful effects and widespread recognition, BHO comes with its own set of disadvantages. As well as being dangerous to make in some circumstances, many preparations are poorly crafted and carry undesirable contaminants, from unwanted plant constituents to solvent residues.

Find out more about BHO below, and learn how technicians are using color remediation column (CRC) extraction to make their products safer and more appealing to the eye, ultimately changing the industry for the better.

What Is BHO?

BHO first hit the scene thanks to a post on Erowid—a forum dedicated to psychoactive substances. The extract has since surged in popularity with cannabis users, mostly because people can make it at home with only a few basic pieces of equipment.

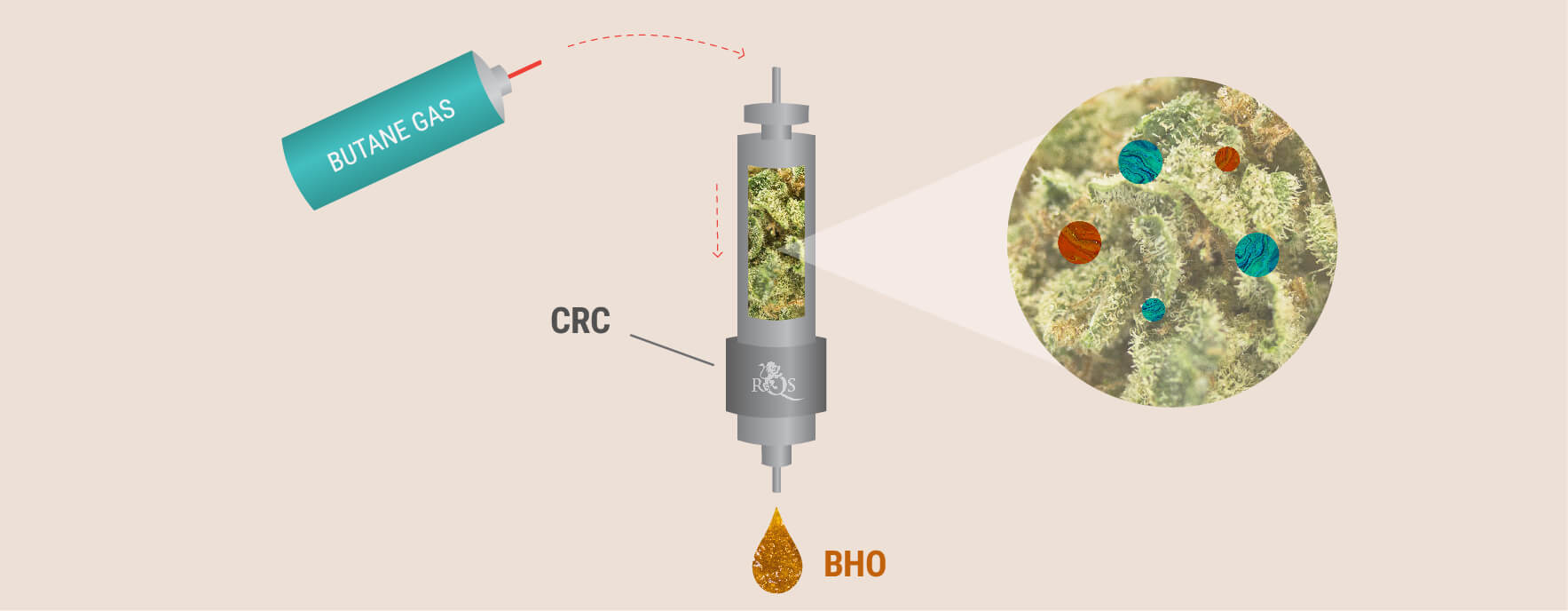

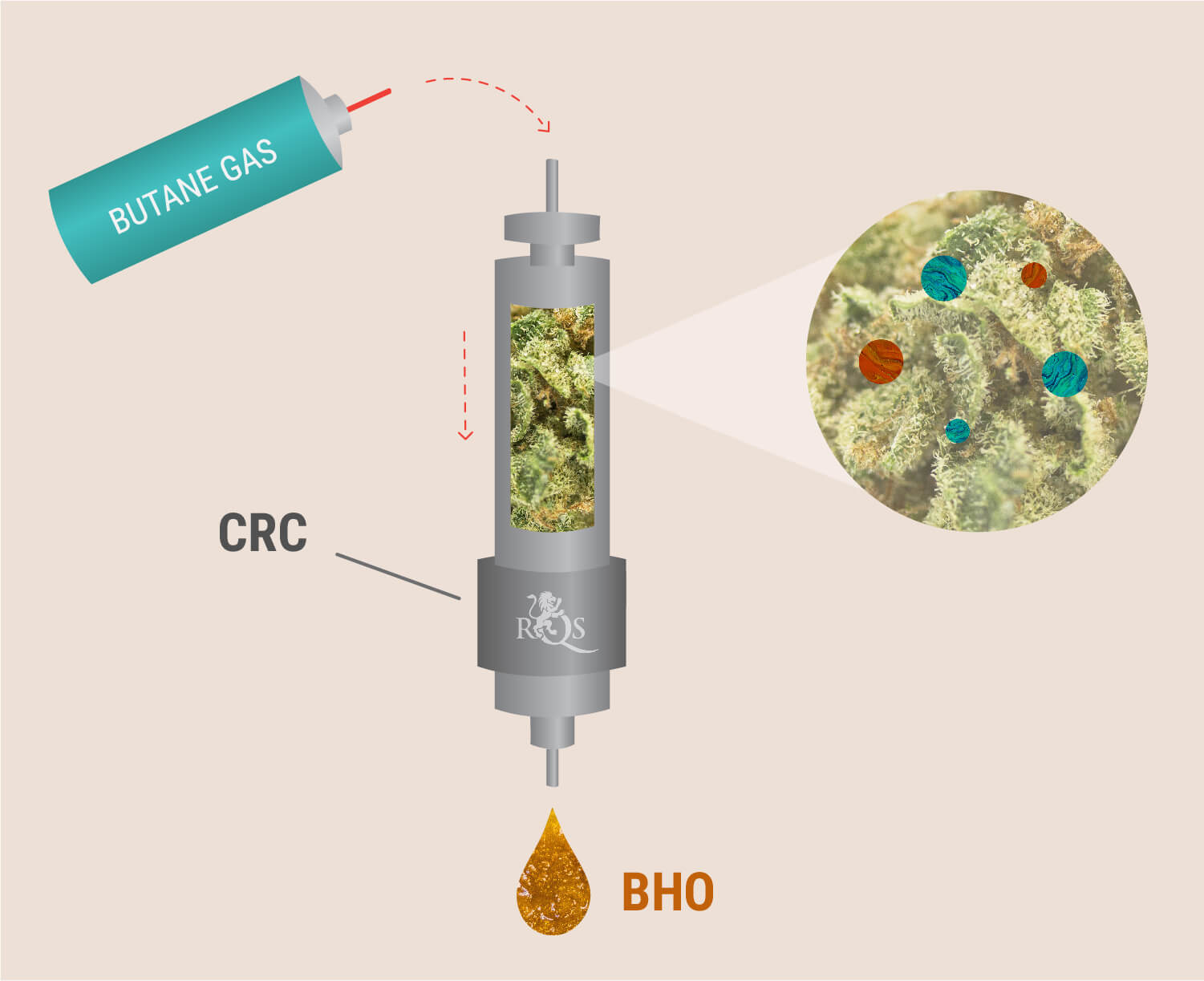

The process involves packing a BHO extractor tube with cannabis and filling it with butane gas. The substance moves through the cannabis and, working as a solvent, pulls cannabinoids, terpenes, and other compounds from the flower material.

The extract emerges at the other end as a liquid infused with precious cannabis constituents. Next, users need to “purge” the crude extract. This step removes the solvent from the mix, but also fills the air with flammable gas, making it a relatively dangerous step when performed in careless conditions. Known as an “open-loop" system, this DIY method allows butane to evaporate and enter the atmosphere.

Several companies in cannabis-friendly states and countries have taken things to the next level with closed-loop systems. This method recaptures the butane and recycles it back through the system, creating an overall more efficient and safer procedure.

Types of BHO

There are several different types of BHO that users can purchase from dispensaries or coffeeshops, or even make at home. Such choice has helped BHO reach its high status within the cannabis world. Each form requires a slightly different process, but they are all made using butane as a solvent.

The most popular BHO extracts include:

Problems With BHO

While BHO serves as an accessible and easy-to-make extract, it comes with a list of problems. First, purging BHO in an open-loop system poses a serious fire hazard.

During the purge, BHO enters the air as a gas. The presence of naked flames or unlikely electrical sparks is enough to ignite the gas and cause it to catch fire. Although it might seem rare, major accidents can, and do, happen. Extract makers in the UK, for example, have blasted walls in their homes in the past.

Second, the quality of BHO varies dramatically depending on the technique used and the experience of the person making the extract. While seasoned extract makers are capable of crafting exceptionally pure BHO, beginners are prone to producing, and subsequently inhaling, impure products.

BHO impurities come in two major categories. Plant constituents make up the first category. Excess chlorophyll, waxes, and other components discolour BHO and make for a harsh and unpleasant smoke.

The second category involves chemical residues. While plant components merely taste bad, inhaling butane does the lungs no favors at all.

What Is CRC?

CRC provides an effective solution to contaminated BHO. Not only does this advanced process minimise the chances of chemical and plant compound contamination, but it vastly improves the visual appearance of the extract.

CRC tech has the potential to change the BHO industry in legal regions, and extract makers in prohibited areas are also using the technique at home to improve the quality of their products.

What Does CRC Do?

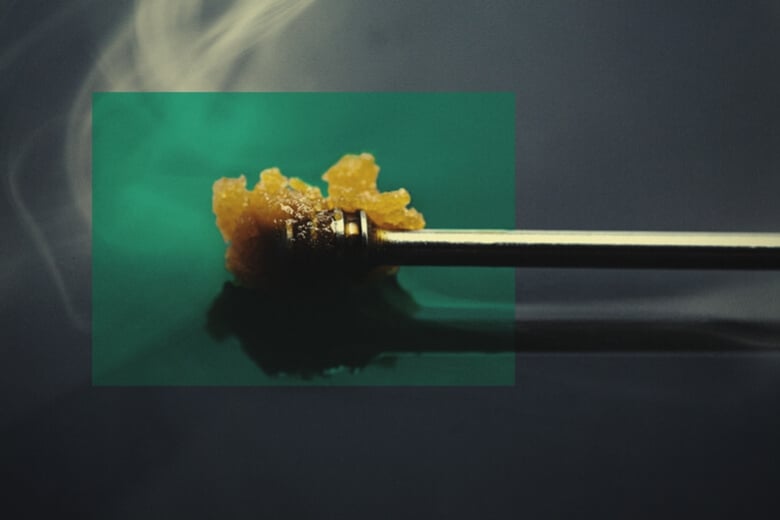

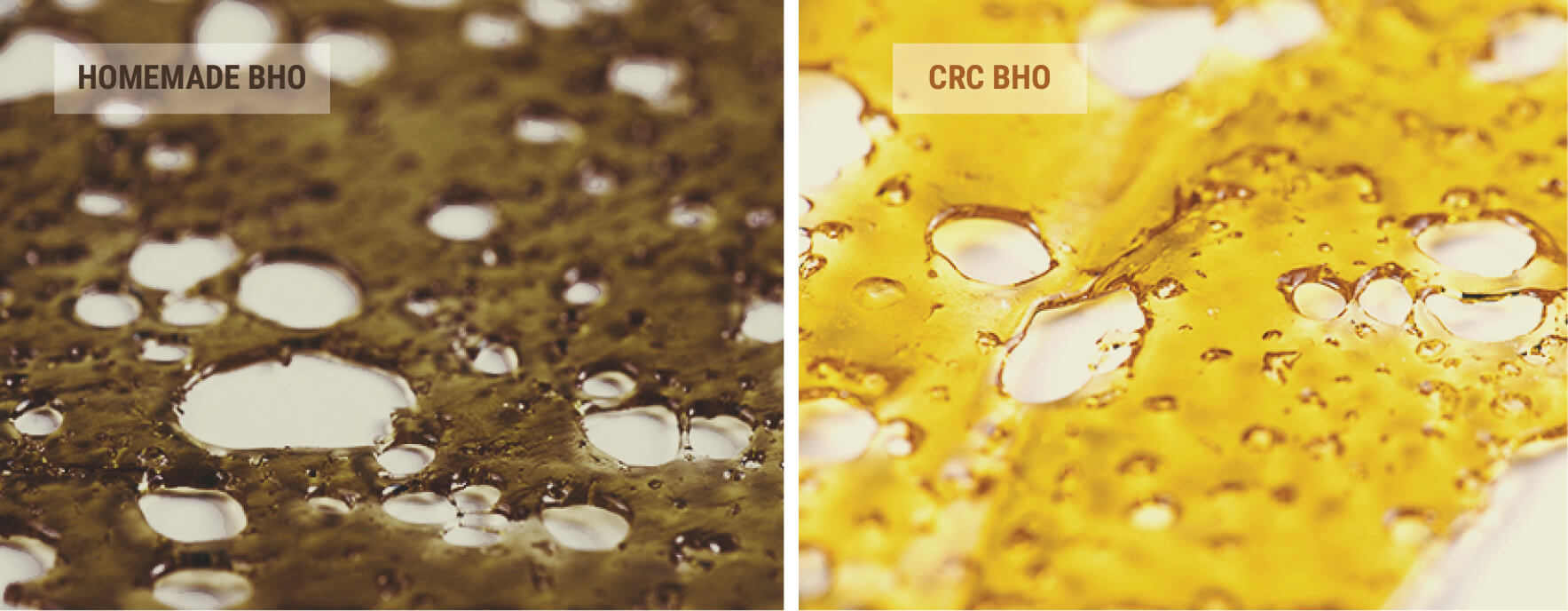

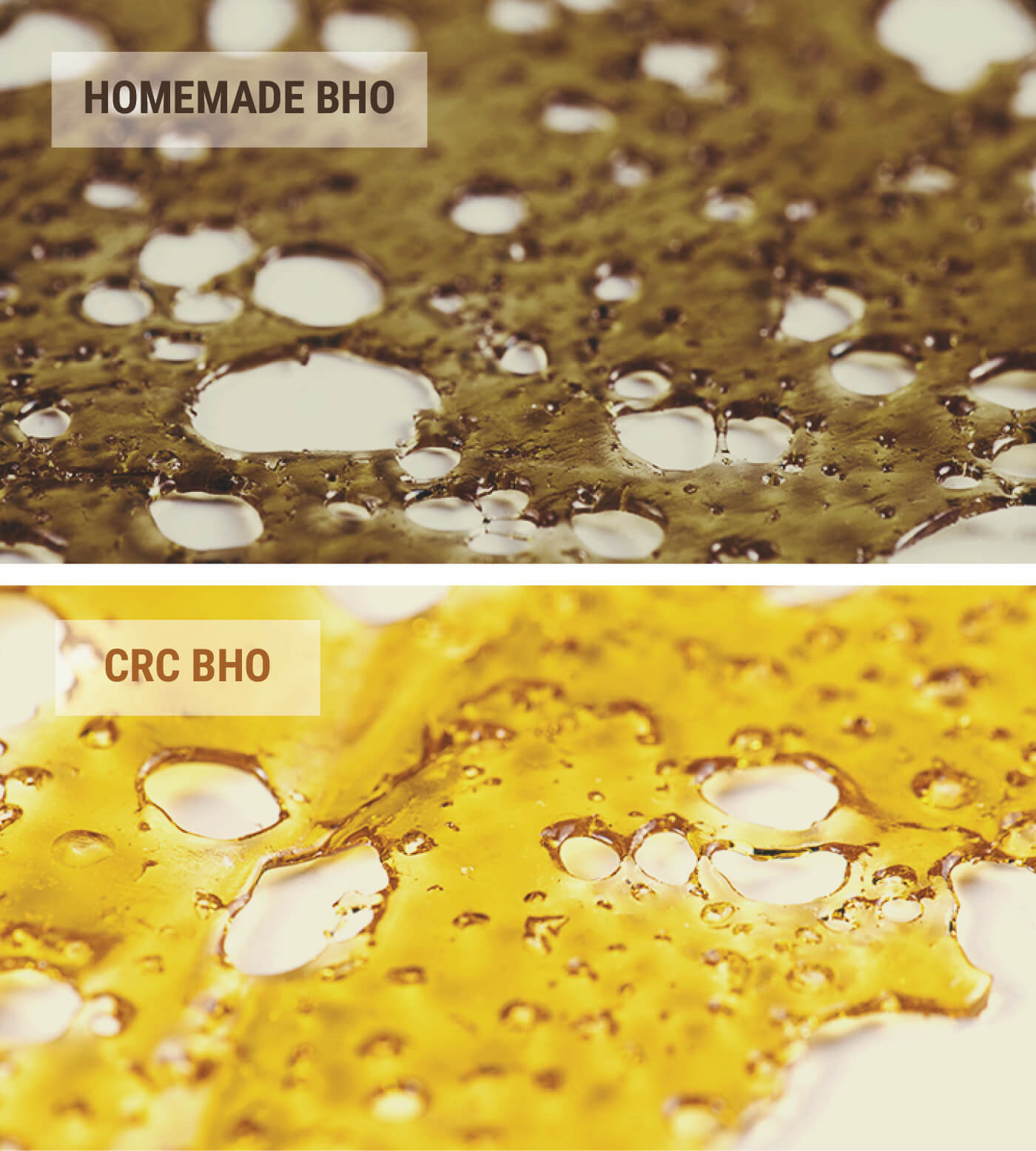

First and foremost, CRC vastly improves the color of BHO. While most homemade BHO is opaque, dark brown, and tastes harsh, CRC creates translucent and brightly colored extracts that are much more pleasing to the eye.

But why should consumers care about how an extract looks? Well, a pure look often reflects a pure product. The bright golden-yellow color of CRC BHO bears testimony to the lack of excessive constituents, which do nothing but take away from the taste and effects of the extract.

Sure, aesthetics do matter, especially in the eyes of customers looking for their next favorite product to blaze. But CRC also achieves something much more important. As well as removing a load of unnecessary plant material, it also helps to prevent contamination at the hands of solvents.

Although current closed-loop systems do a great job of removing butane residues, CRC systems take things to the next level. Through the use of an additional layer of filters, this method captures all traces of solvents and prevents them from winding up in the final product.

The CRC Process

Extractors can achieve better color and purer products by simply adding one more step to the extraction process. Just like a normal BHO setup, CRC rigs feature a solvent tank, a material tank (where the solvent pulls all of the cannabinoids and terpenes), and a collection tank. However, the addition of a CRC column between the material tank and the collection tank makes all the difference.

The CRC column contains several layers of materials that work to filter contaminants from the extract. These materials vary between setups but commonly include bentonite clay, synthetic magnesium, and silica gel.

After the crude extract enters the CRC column, it passes through several layers of these filtering materials. After making it through the initial barriers, the filtered oil then passes through a paper filter and finally a filter plate to determine maximum purity.

Can CRC Tech Fuel Extract Industry Growth?

CRC will definitely make a positive impact on the BHO industry in legal nations and states. As companies continue to embrace this method, customer satisfaction and confidence will expand. Manufacturers can offer higher levels of purity, better-looking products, and extracts with improved tastes and effects.

What Are the Downsides?

Does CRC have any downsides? When it comes to a commercial setting, not really. The only downside of the method lies in making extracts at home. Artisan makers can use CRC tech to improve the quality of their products, but incorporating it into an open-loop DIY system means more effort and investment.